We recommend you get a seven point preventative cooling system maintenance check performed at least once every two years. Consult your vehicle owner's manual for specific guidelines. The cooling system inspection identifies areas that need attention, and consists of the following:

•A visual inspection of all cooling system components, including belts and hoses

•A radiator cap pressure test to check the recommended system pressure level

•A thermostat check for proper opening and closing

•A pressure test to identify external leaks to the cooling system parts including the radiator, water pump, engine coolant passages, radiator, heater hoses and heater core

•An internal leak test to check for combustion gas leakage into the cooling system

Cooling System Operation

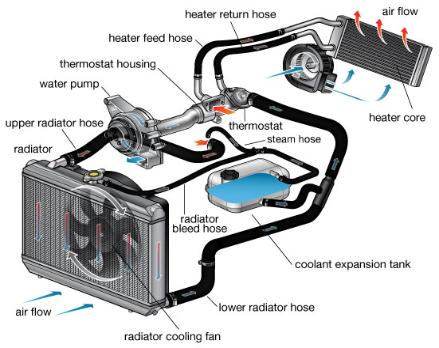

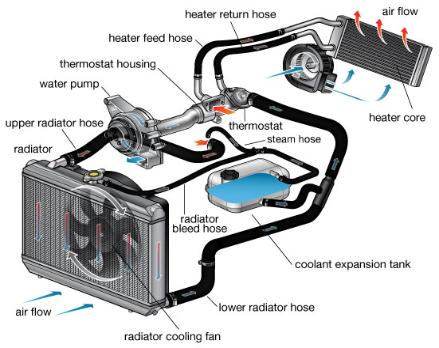

The Cooling System carries heat away from the engine and maintains the operating temperature by circulating anti-freeze/coolant through the engine, and carrying it to the radiator for cooling.

Modern automobiles operate in a wide temperature range, from well below freezing to over 100 F. The fluid used to cool the engine must have a low freezing point, high boiling point, and the ability to transfer heat. An adequate amount of antifreeze/coolant and water reduces the possibility of engine over-heating and freezing, as well as contains additives to prevent rust and corrosion in the cooling system.

Water holds heat well; however, water alone freezes at a temperature too high to be used in engines. The fluid in most vehicles mixes water and antifreeze or coolant. With this mixture, the boiling and freezing points improve significantly.

Coolant temperatures sometimes reach 250 to 275 degrees Fahrenheit. Even with antifreeze added, these temperatures boil the coolant. To prevent boiling, the cooling system raises the coolant boiling point by pressurizing it. Most systems pressurize coolant at 14 to 15 pounds per square inch (psi) which raises the boiling point approximately 45 degrees Fahrenheit

Visual Inspection

* Interior controls and blower

* Radiator coolant level, hoses, pressure cap and thermostat

* The A/C compressor belt for condition and tension

* Leaks or other damage

* Component condition, leaks or damage

Heating and Air Conditioning Tests

* Pressure test engine cooling system

* A/C system pressures are measured and compared to manufacturer's specifications

* A/C system is leak tested

* Both the heater and A/C are performance tested by checking the outlet air temperature at the discharge vents